Technologies | Digital Control

Advanced digital control at the core of innovation

ICERGi Digital Control Capabilities

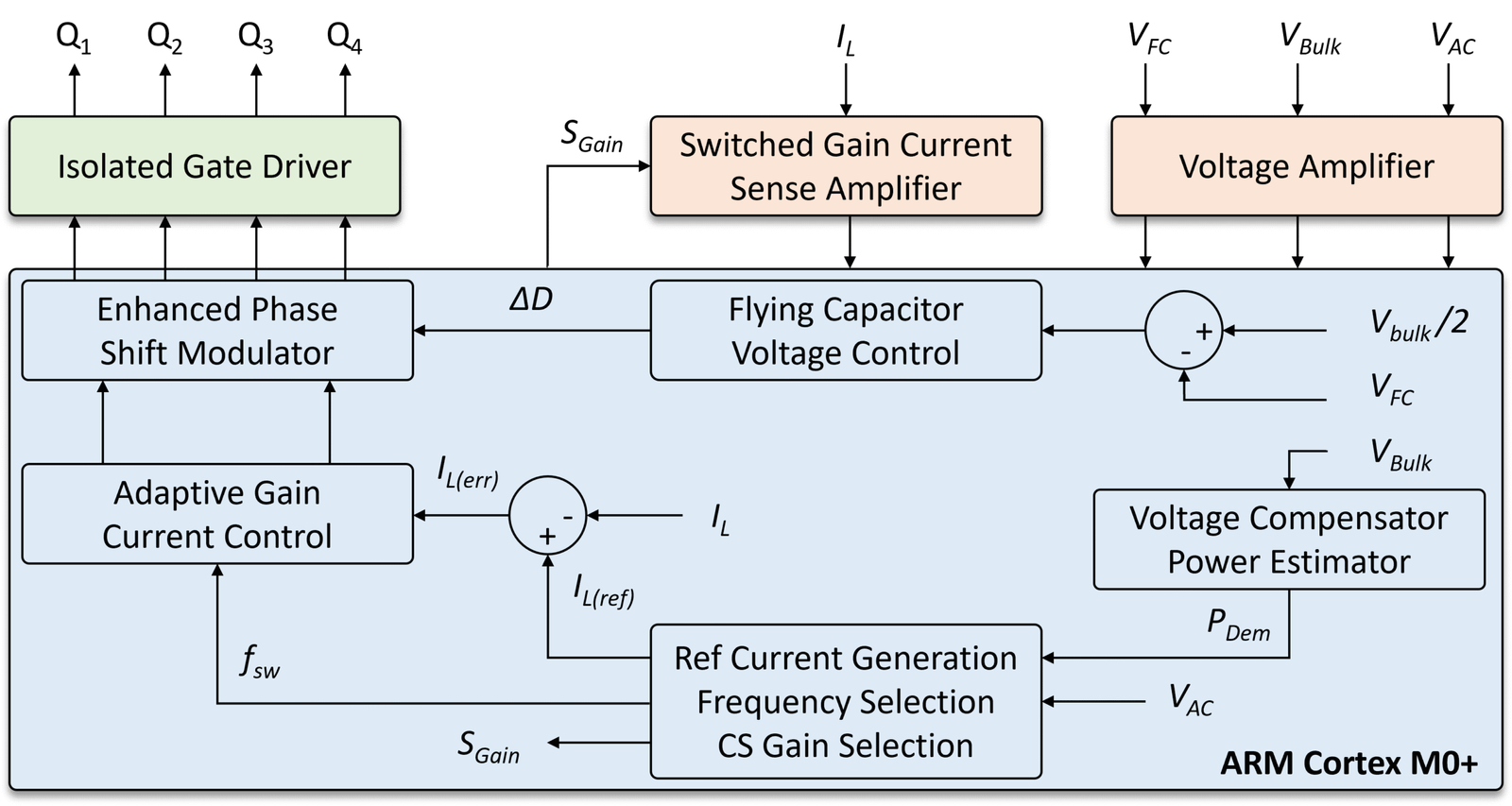

ICERGi specializes in advanced digital control of PFC converters, leveraging high-performance, cost-effective ARM® Cortex™-M0+ microcontrollers with rich peripheral sets and a mature development ecosystem. This platform delivers a robust and efficient foundation for implementing precise, real-time control of PFC systems.

Combined with ICERGi’s proprietary control algorithms and scalable, low-cost hardware architecture, it enables compact, reliable, and high-efficiency power conversion across a wide range of applications.

Built on the proven ARM® Cortex™-M0+ processor, our solutions are typically implemented on compact, plug-and-play digital control daughter cards. These cards feature integrated gate drivers and auxiliary circuitry, forming a complete control and drive suite for power conversion systems.

Designed for seamless integration, they support applications up to 5 kW and beyond. Proven in the field and backed by a robust development framework, ICERGi controllers deliver exceptional efficiency, flexibility, and scalability across various PFC power levels.

Specific Advantages

- Enables up to 99.3% in PFC efficiency with 150V Si or 400V SiC MOSFETs in practical implementations.

- Proven active and passive control techniques ensure stable flying capacitor voltage under both steady-state and transient conditions.

- Proprietary fast and sophisticated protection for flying capacitor voltage during abrupt events, such as input surges or transients. – Find out more

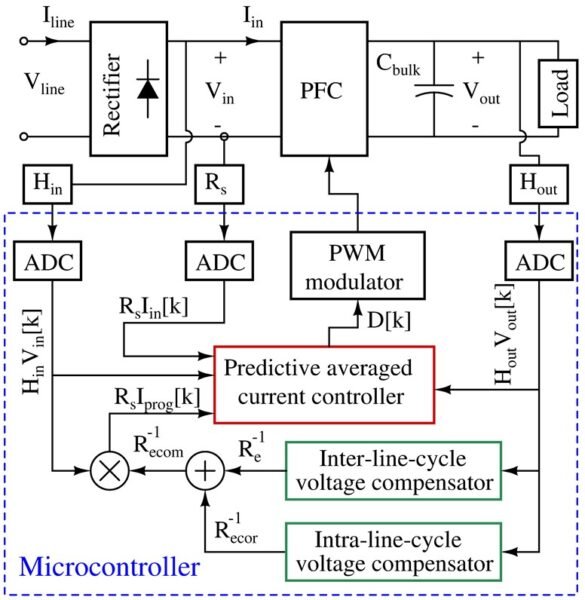

- Advanced predictive current control with intra-line-cycle compensation to enhance dynamic response and power quality across different operating conditions.

- Implemented on the widely popular, low-cost Cortex M0+ processor, with seamless integration and upgrade options to more advanced MCU architectures (ARMv7-M, ARMv7E-M).

Key Features

- Multiple PFC operating modes, including variable switching frequency, adaptive gain control, reduced conduction angle, burst mode, and EMI reduction during zero crossing.

- User-configurable PFC parameters accessible through a custom-developed graphical interface for easy tuning and system optimisation.

- Compact control and drive suite in a 40 mm x 30 mm form factor with a streamlined, cost-effective BOM.

- Optimised for a broad power range from 1kW to 5kW and beyond, the control and drive suite scales seamlessly without requiring modification.

Solutions in Action

Variable switching frequency with Adaptive Gain Current Control

Traditional CCM boost PFC converters typically operate at a fixed switching frequency, which often leads to significant switching losses at light load and reduces overall system efficiency. ICERGi’s proposed control arrangement dynamically adjusts the switching frequency to minimize losses under varying load conditions especially in light and medium load scenarios without compromising power factor and ATHD.

This technique has been successfully implemented in a 3 kW bridgeless totem-pole PFC platform, achieving peak efficiencies above 99% at 230 VAC, even with diode rectification. Scalable up to 5.5 kW, this solution is applicable across a wide range of hard-switched PFC designs. It enables more efficient front-end power stage design at light to medium loads, with improved thermals and greater performance margins.