Technologies | Multilevel Power

High-efficiency power conversion with multilevel PFC

Introduction to Multilevel Technology

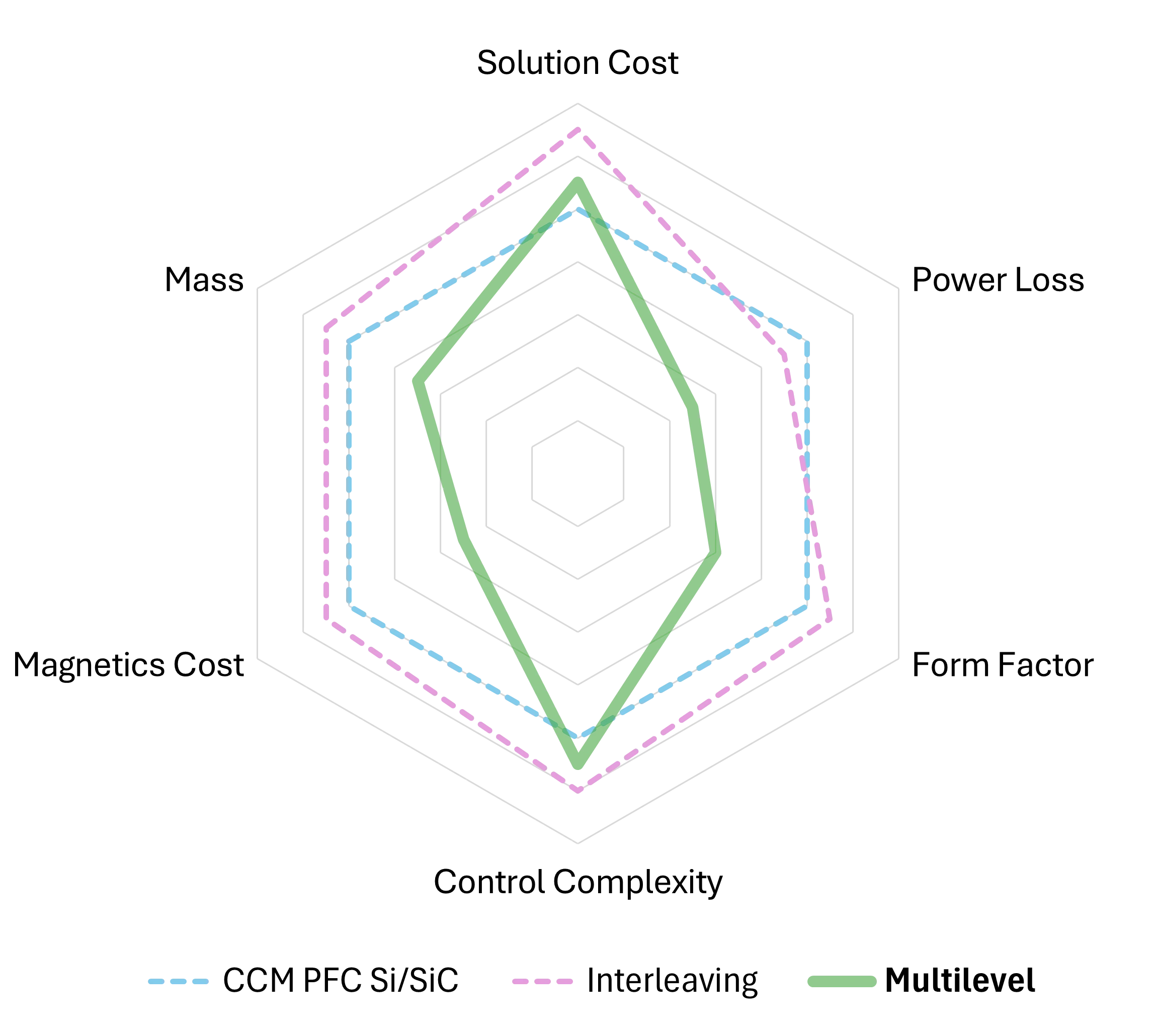

Multilevel Power Factor Correction (PFC) technology enhances power conversion by employing multiple voltage levels to achieve lower total harmonic distortion (THD), reduced switching losses, and lower electromagnetic interference (EMI). Compared to conventional two-level PFC, Flying Capacitor Multilevel (FCML) PFC distributes voltage stress more evenly across semiconductor devices, allowing the use of lower-voltage-rated components with improved efficiency.

Additionally, by enabling higher effective switching frequencies and better waveform shaping, multilevel PFC can significantly reduce the size of passive components, particularly inductors and EMI filters, resulting in a more compact and thermally efficient power stage design.

Why Multilevel PFC?

- Highest Efficiency

Lower switching losses and reduced output ripple drive system efficiency above 99%.

- Low Voltage Stress

Devices switch at a fraction of the total bus voltage, enabling the use of lower-voltage, faster-switching MOSFETs.

- Superior Thermal and EMI Performance

Lower dv/dt and di/dt translate into easier thermal management and simpler EMI filtering.

- Scalable and Flexible

Multilevel PFC can be tailored for various power levels (700 W – 5.5 kW) using standard components and a flexible hardware arrangements.

Feature / Topology |

Conventional PFC |

Interleaved PFC |

Multilevel PFC |

|

Circuit Complexity |

Low |

Medium |

Medium* |

|

Efficiency |

Moderate |

High |

Very High |

|

Input Current Ripple |

High |

Low |

Very Low |

|

EMI Performance |

Moderate |

Improved |

Excellent |

|

Thermal Distribution |

Single Path |

Spread |

Distributed |

|

Component Stress |

High |

Reduced |

Much Lower |

|

Control Complexity |

Low |

Medium |

High* |

|

Scalability |

Limited |

Good |

Excellent |

|

Size and Weight |

Moderate |

Slightly Larger |

Compact |

* ICERGi’s turnkey control and gate drive technology enables practical adoption of multilevel PFC in real-world systems.

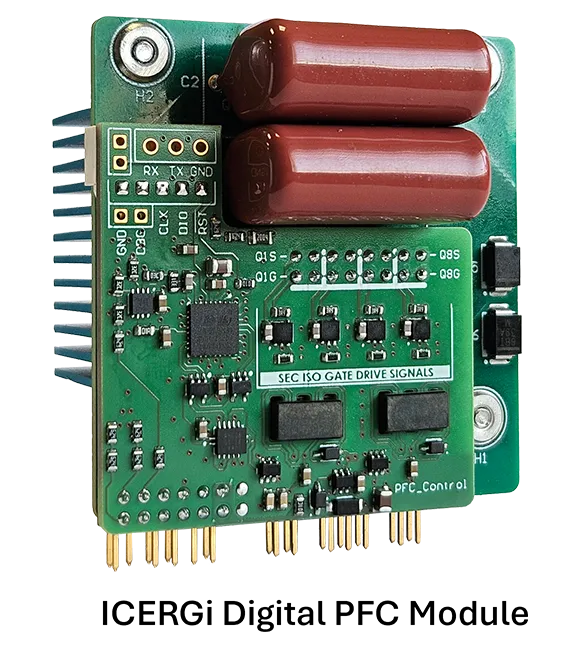

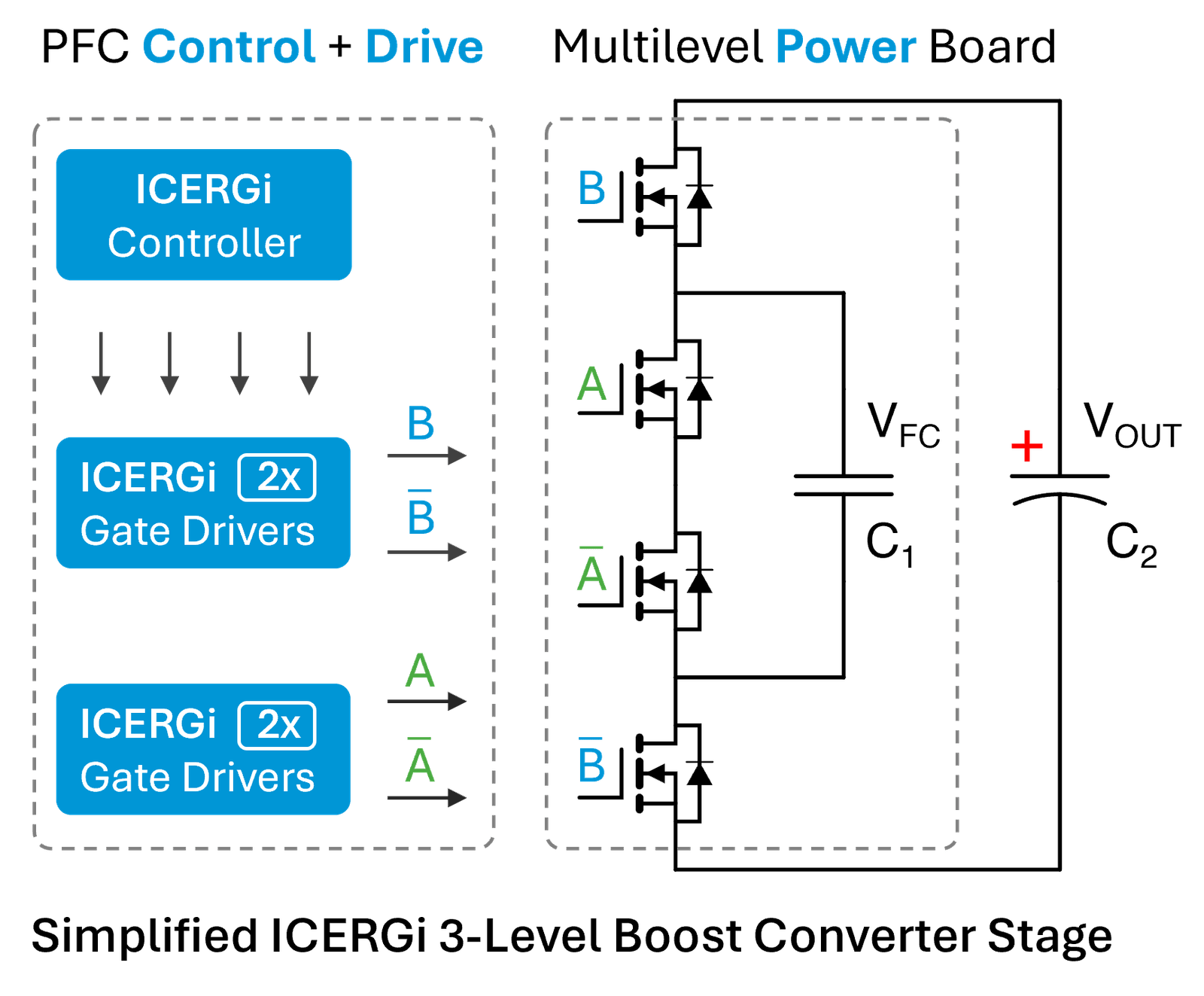

ICERGi Multilevel Architecture

ICERGi has developed a multilevel boost converter architecture that separates the power and control functions for maximum design flexibility. The solution uses a two-board approach: MOSFETs are placed on one power board, while a dedicated gate driver array and the digital microcontroller ecosystem resides on a control daughter board. This modular structure enables ease of integration, thermal optimization, and compact layout. Backed by proprietary IP, ICERGi’s multilevel implementation supports seamless integration with a large range of Si and SiC switching devices. It paves the way for broader adoption of multilevel power technologies and creating new value opportunities for designers of high-efficiency, high-power front-end power supplies.